|

Alternate

Way

to Repair Sagging Mirrors

By Homer

Dawson

First with a

small

screw driver, pop the outer ring of the mirror loose, next remove the

mirror (be very careful not to break the mirror), this will reveal the

10 mm bolt that needs to be tightened, once this is done replace the

mirror, then, with a drop of silicone or glue, re-install the outer

ring back on.

Speedometer

Error

Problem: The

speedometer is in error by a plus 10% (five to six miles per hour at highway speeds.) In other

words, when it reads you are going 60 MPH, you are in reality only

doing 54 MPH.

Solution:

The gear located at the end of the speedometer cable

(on the front wheel) has 25 teeth. If the number is reduced to 23 or 24

teeth, the speedometer will then read close to true. Carl Leo finds that

the 23T gives accurate speeds with a Dunlop Elite 3 tire at 38 lbs psi.

The receiver for the speedo at the front wheel must be replaced

with Kawasaki Part No. 41060-1025 (24t) or 41060-1107 (23t.) You must also put in a new oil seal,

Kawasaki part No. 92049-1057. While you are at it, replace the pinion gear or you are asking

for trouble down the line mixing new gears with old. The part number for the 9t pinion gear is 41060-1016.

An installation tip from Carl: "It is easy to damage the housing trying to disassemble the unit and I see

some that look like kindergarten children worked on them. Be gentle........."

Installation tips from Doug Divine of South Florida: "You have to drill a hole

(same size as roll pin) in the hsg on the opposite end of the roll pin so you can push the

roll pin out. The small hsg that holds the pinion in is pressed in, you need to grip it

good and work it out & it is alum so do not bugger it up to bad. The seal will come out

fairly easy with a screwdriver just pry in different spots, If you are easy with it it can be

reused if need be. I use a marine white lithium waterproof grease, Do not use wheel bearing grease

or a thick heavy grease. Check that the lock or collar with the two big notches that fit in the

wheel are not chewed up, if edges are dinged up you can file them so they are straight, if real

bad you you need to replace and be sure when you put hsg back on that it is set in properly, The

housing where the cable is attached should be almost parallel with the floor. The speedo hsg looks

like it fits between two stantions on the shock but it does not, Look at the way it goes before you

remove it. Cable should go up thru fairing on outside of shock and I always put a small o-ring on

bottom end of cable to keep water out and do not loose little washer on the end of cable and ones on

the pinion. Actually takes longer to type this than to fix it. Like Carl says some are better off just

replacing the whole assy. But I do not think you can get the correct gears that way."

Note that this change will also reduce the odometer reading. I've found the stock odometer reading

to be off only 2-3% instead of the 10% of the speedo. Your observed gas mileage will appear to drop!

Balancer

Gear Backlash

Adjustment

Problem: Many have

complained about Voyager XII gear whine or transmission noise. Although

the Voyager XII has straight cut gears in their transmissions due to

the desire for a more sturdy and reliable transmission, straight cut

gears compared to helical cut gears do make more "gear whine". However,

some time it may be something more than the normal, mostly unobtrusive

straight cut gear whine that you might hear. It could very well be that

the balancer gear backlash needs adjustment.

Solution:

A fairly simple adjustment

may be

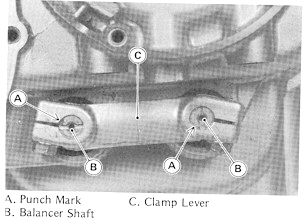

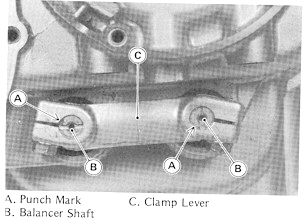

needed to the balancer gear backlash, here's how to do it (refer to the

picture below):

|

|

You need to look on the right side of

the engine (sitting on the bike) to find the balance shafts clamp

lever- pictured to the left. The punch marks on each shaft should point

to the correct side. The mark on the front shaft points to the rear.

The marks should point in the direction as shown in the photo (to the

rear). Then: |

- Start the engine and let

it at

idle.

- Loosen the balancer shaft

clamp

bolts.

- Turn the front balancer

shaft

clockwise until the balancer gear makes a noise.

|

- Turn back the shaft

counterclockwise until just the gear stops making a noise.

- Adjust the rear balancer

shaft

in the same manner.

- Tighten the balancer shaft

clamp

bolts securely.

|

Keeping

Music Tapes Tight

From

AVA Member Archives

By Ed Cones

After a short while, cassette tapes will "unwind" in the Voyager tape

storage compartment and have to be rewound before you play them or they

could get fowled in the tape player. Ed submitted two methods for

keeping his tapes tight enough to play without having to re-wind them

after storage before playing.

"I've used foam earplugs in my

tapes since I got the bike. They work well, Just roll 'em down like

you're at the shooting range except stick them in the tape."

He also experimented during a long cycle trip and came up with the

following: "If the tape is rewound completely or almost completely,

looking at them from the rear of the bike, the large spool turns

clockwise. So, I rewind my tapes before removing them from the player

and place them in the storage compartment with the full spool down and

the open side of the tape to the right or center of the bike. The

clockwise movement of the large spool keeps them tight. This has worked

great on my bike for 10,000 miles now."

Recall

Notice

Clutch

Back Torque Limiter Warning

Dated November 1999

"Kawasaki Motors Corp., USA has

determined

that a defect which relates to motor vehicle safety exists in 1999 and

2000 model Ninja ZX-7R, Concours, and Voyager XII motorcycles. On

eligible units, the back torque limiter in the clutch may malfunction

and allow the clutch to slip, or not re-engage after a shift. This

sudden non-engagement of the clutch might cause the rider to lose

control of the vehicle, possibly resulting in an accident and personal

injury."

This notice was probably

delivered to all owners for the years and models mentioned above, but

anyone purchasing a used cycle should check to verify that this safety

defect was corrected. Owners previously unaware of the defect should

contact the nearest Kawasaki dealer for further details.

Battery

Sensor

From

the AVA Archives

It seems as though quite a few times the

question has been raised on how to disable the battery sensor on the

VII so the battery light stays out. Some basic observations for the

unknowing should first be considered:

-

The battery

lights purpose is to indicate that the battery electrolyte or water

level is low in the battery. This is handy so you don't need to check

the level so many times during the riding season since it's not the

quickest thing to do.

-

The battery

light

has nothing to do with the quality or life left of the battery, other

than letting you know the water level is low. If the water level in a

battery is left low, it will cause sulfation in the battery cells and

lead to pre-mature battery failure.

-

Most

manufacturers make at least two versions of a battery that will work

for the Voyagers, one with, and one without the battery sensor. Some of

the newest batteries such as the gel batteries, or a maintenance free

battery, prevents you from adding water by design. If you would like

the convenience of the battery sensor and want to use the standard

non-maintenance free batteries, then buy the ones with a sensor. If you

get a maintenance free battery, then you don't need to worry about that

option and will probably just pay a higher price for the battery.

So after you decide which battery you would like to use, and have

decided on a gel, maintenance free, or simply one without a sensor

hookup, then you probably will want to disable the sensor by simply

connecting the sensor lead to a +12 volt source. This can be done by

either using one of the spare leads under the fairing, or simply

connecting it to the +12 volt terminal of your battery. Others have

suggested to hook a 100 ohm resistor in line with the original wire

going to the battery and terminate it at the positive battery terminal.

Changing

the XII Spark Plugs

By

Ed

Cones from AVA Archives

Changing out or cleaning the spark plugs

on

the Voyager XII is not a slam dunk, easy job. It can be made easier,

however, if the battery and battery tray are removed. The Voyager XII

comes with a tool pack that contains a spark plug tool. Using the tool

with an extension and a pair of long needle nose pliers to reach the

plug wire caps makes the job a bit easier.

Please remember to clear the

plug area with air pressure before removing the plugs. Each of the plug

locations will collect bits of stone, dried bugs, and other debris. It

must be cleared in order that the contaminants do not fall into the

spark plug hole when the plugs are removed.

Temperature

Gauge Fix

From

AVA

Archives

It has been reported that several have

had

problems with the Voyager XII water temperature gauge reading either

low or not at all. It has been traced to an inadequate ground. The fix

for this involves checking the grounding for this gauge. You can make a

small ground wire to run from a thermostat housing (which contains the

temperature sender) bolt up to a 6mm bolt in the frame just behind the

steering head, or another good grounding point.

Intermittent

Electrical Problem

(headlight,

gauges, brake and tail)

From the

AVA

Archives

By Denny

Zion

Problem:

Occasional loss of headlight,

fuel

and temperature gauge readings, as well as tachometer, brake and tail

lights. Interruptions usually occur periodically. Loss could become

more numerous as time goes on. Fuses appear or check out OK.

Solution:

More times than not, a problem exists

with the

large connector just after the fuse block. Possibly caused by excess

water or dampness otherwise getting into this connection. The

electrical connection within this connector (plug) becomes corroded to

the point that it makes intermittent contact with it's opposite pin

that powers these items. Disconnect this plug and thoroughly clean all

the pins on both sides of the connector. A good electrical cleaner

should do the trick (such as electrical contact cleaner at a

electronics store, or comparable). After all contacts or pins are

cleaned, a good application of electrical anti-corrosive grease

(usually for aluminum cable- available at electrical contractor stores)

should prevent this from happening again.

Brake

Light Switches

From

the

AVA Archives

By BJ

Reynolds

Problem:

The front or rear brake switch

fails

to activate the brake light when the lever or foot brake is applied.

Solution:

Loose spade connector(s) may

be the

problem. A slight crimping of the connectors should take care of the

problem. It is suggested that you frequently check both the lever and

foot brakes to make sure they are activating the brake lights as they

should.

Clarion

Radio

or CB Service Procedure

Clarion

no

longer services the Voyager XII radios or CB's.

However,

there

are still two outlets where service can still be obtained at this time.

The first outlet we recommend is service and modifications provided by

Peter Franchi. He can be contacted through his email by clicking

here. He can also be contacted through his username

(suzib6sw) on the AVA Message and Information forum here.

The

other

source of service is noted below.

Sierra

Electronics does repair the radios and CB's from Voyagers XII's!

As of

2/17/09, they indicated that they had a 2-week turnaround from date of

receipt of the radio or CB. The typical cost for a repair on

either component is $100. When you send it in, they will go

through it and when they have a firm price, they will contact you for a

credit card to pay for the repairs. If there is anything

excessive, they will let you know BEFORE doing the work.

Their

contact

information is:

Sierra Electronics

2080 Experiment Farm Road, Troy, OH 45373

800-338-6938 / 937-335-8939

Sales@sierra-mc.com

For

more

details on packaging the radio or to confirm turnaround time, contact

them directly.

Easier

Battery Level

Checking

By

Chuck

Tenwick

From AVA

Archives

Problem:

Finding an easier way to check

battery electrolyte level without having to remove battery to see level

lines and associated having to disconnect battery leads etc. to do so.

Solution:

The normal level checking lines which

are on

the front of the battery are not easily read since they face the front

of the motorcycle, therefore, Chuck suggests that the next time you

have your battery out, to draw a line on the back side of the battery

with a magic marker indicating where the full level line is for the

electrolyte solution. This way, a quick look with the dummy tank off is

all that is needed to know where your level is in the battery. He also

mentions that he wads up a small piece of paper to stuff under the nuts

for the terminal bolts. The wads act as springs to hold the nuts in

place when starting the terminal bolts.

Broken

Rear Speaker Mounts- Temporary/Emergency Fix

By Tommy

James

From the AVA

Archives

If the problem is the metal plate separating from the rubber bushing,

place a small drop of super glue type adhesive between the metal plate

and rubber bushing. This fix will work just fine without any problems. Make

sure the metal plate and mating surface of rubber bushing is clean-

even of previously used super glue if broke before, then apply glue and

lower bushing onto it. Weight of speaker should hold it firmly enough

until cured. Allow at least several minutes before riding off to allow

sufficient cure. Also, avoid any oversize packed touring bags placed on

the luggage rack that may tend to spread apart the speakers.- Gary,

Webmaster

Broken

Rear Speaker Mounts- Permanent Fix

Original

Solution

By Bob Hughes

Rewritten and Photos added By Gary Schill and Lori Norris

Using Bob

Hughes' original

article

for fixing broken speaker mounts more permanently, we have expanded the

instructions and included photos. Bob

reports that this repair has proven successful for the last 60,000

miles and 6 years of terrible Michigan roads around the Detroit area.

|

|

|

Here

is a problem that plagues many Voyager XII riders, broken speaker

mounts. The rubber part of the mount usually separates from the metal

backing plate and voila, you

have a bouncing speaker. |

1. To start, remove the speaker mounts from

the speakers and rear luggage rack. There are 3 nuts on each speaker to

remove them from the rack. When

removing two screws each that hold each

of the three rubber speaker mounts, reinsert at least one screw to hold

speaker together. If re-using the broken mounts, first re-glue them

back together to keep them lined up. |

|

|

| 2.

Next will be to drill out the

center of the speaker mount stud with a #43 drill bit. These are a wire

gauge drill bit available at better hardware stores. Use

caution when drilling the hole to keep it straight and centered in the

stud as there is not much room for error. |

3.

Then it's time to tap out the hole you just drilled in the speaker

mount bolt. Use a tap to thread the hole for a #4 metal screw with a 40

pitch thread. Use oil while tapping out the hole, and be very careful

while tapping so you don't break the tap. Advance a little while

tapping, then back out. Repeat this a few times, then withdraw the tap

and flush the hole with oil and repeat until the hole is completely

threaded. |

|

|

|

4.

With the hole now tapped out, use a #4 x 1½"

metal screw. Apply thread locker to thread first, then turn in screw

from the top down until it tightens just slightly so the mount can

still flex some. |

5.

After screw is in and very slightly snug, cut off excess flush with

speaker mount stud. |

|

6.

You should then drill a small divot in the speaker housing to allow

room for the screw head. We also used one aluminum back-up washer for a

⅛" pop rivet

for

each mounting screw. Be sure all the lock tabs on the speaker mounts

point to the center of the speakers to align with the luggage rack

cutouts. After all the speaker mounts are mounted to the speakers,

remount the speakers to the luggage rack and screw on the nuts removed

in step one above.

| TIP:

When installing nuts especially towards the top trunk hump, it is

easier to start the nuts when the top trunk lid is open. |

|

Another

Alternative Fuel Pump Suggestion

By David Randall

In case you

cannot

get the fuel pump that Jeff talks about above, NAPA

does have an electric fuel pump that will work. It is part number

610-1051, Posi-Flo model. It comes with an add on filter that goes

between tank and pump, and all the fittings, but not any extra fuel

line. You will need a little extra to to locate the Voyager original

fuel filter and to add a little between pump and tank. This pump is set

1.5-4 PSI two wire design, neat and small, will mount on the regular

mounting bracket that the Voyager pump is now on (with just a little

rigging). It also will let you relocate the fuel filter so you can

change it easier. Instead of using the long fuel line adapter that goes

in the outlet end, use an elbow first, then, the adapter. Use the info

Jeff provides about wiring the pump. I used the red hot wire and ground

Jeff talks about, but did not cut the original plug off. Be sure to

mount the back as far as you can on the original mount so the rear

brake reservoir will remount with no trouble. AFter installing the pump

and before putting everything back in place, I checked to make sure

that everything would fit back i place just like factory. Turn the key

on, wait just a minute to let it prime up. Instant start and very

little gas fumes. Down the street and back, using all the throttle I

could, yielded very good throttle response and very smooth running at

last. Total cost for pump and supplies are $60.00 (as of 11/18/07),

much better than the OEM at $175 for a new pump.

Discharging

Battery

By

Gary

Schill

Problem:

The battery seems to discharge

over

about a 2 to 3 week period just sitting in the garage until it won't

start the motorcycle. "It seemed OK when I first parked it, but a few

weeks later, it wouldn't turn the bike over".

Solution:

On the Voyagers, there is a

constant

drain on the battery even when sitting idle, this is because the memory

in the radio, clock, and if so equipped, the CB take a little electric

to maintain their settings. Even if your battery is fully charged when

you park your bike for a extended idle time without riding much, the

battery can easily become discharged enough to not start your machine

in a couple or so weeks. This is normal. This constant discharge and

then charging when you do ride your bike can cause sulfation of the

battery plates, and eventually or prematurely your battery will die. To

best combat this sulfation of the battery plates and keep your machine

ready to ride, you should invest in a "smart" battery charger. The two

most well known brands are the Battery Tender and

the Battery Minder, although there are other brands

manufactured. You can simply hook up the usually provided ring terminal

battery cables to your bikes battery, and when you park your bike for

any amount of time, just plug it in to the battery charger. You can

leave the charger connected indefinitely until you are ready to ride

again, then just disconnect the polarized connector, and you'll have a

fully charged battery ready to go. The charger goes to maintenance or

standby mode until the battery needs a charge to keep in top condition.

This reduces drastically the sulfation problem, and you always have a

fully charged battery ready to ride.

Starter

Chain/Igniter

By

Charlie Sargent

Problem: The starter

chain breaks.

Solution:

This problem was present in

the

Voyager XII model years of '86 and '87. It would usually occur when a

discharged or failing battery was used to start the machine. If you own

an '86 or '87 Voyager XII, it is recommended that you check to be sure

you have the updated igniter to prevent this problem, replacement of

the starter chain with the updated one may or may not be

necessary. Also, keep your battery (all year Voyagers too)

fully charged and in good condition. The following information was

provided by Charlie Sargent who experienced this problem and it's

solution first hand- THANKS SARGE!!

"There have

been

86's/87's that broke the starter chain tensioner and tossed a chunk of

it through the engine cases. A few common traits among all the starter

chain failures are, all were '86/87' models, which had the old starter

chain (p/n 92057-1205). There was an update to a newer chain (p/n

92057-1276), 1986/1987 had the old-style igniter (p/n 21119-1179),

which had problems with over-advancing the ignition timing. The new

style igniter is (p/n 21119-1248) you can check which igniter you have

by removing the tank cover and check the part number on the igniter

box. All machines that experienced failures seemed to have had low

batteries that cranked the machine over slowly sometimes and then turn

over normal other times. (It put a lot of stress on the starter chain

until it failed.)"

Installing

Progressive Fork Springs

By

Gary

Schill

OK, you've decided your

front

fork

springs are sacked out, or would like the best performance and ride of

the Progressive springs. You might think all you have to do is take the

old OEM's out and replace with the Progressive's, but there is a

difference in the springs that will require you to change the

re-assembly process. The process of changing springs (as well as fork

oil) is not all that hard, but is more difficult than changing either

one on some other bikes. So here's the process:

The fork springs you

need are Progressive Part No. 11-1102 for '87 thru '03, (1986

Voyager XII's use

Progressive Part No. 11-1122), these are Progressive's numbers, it may

be listed under a different part number depending on the dealer or

distributors numbering system- check their listing for the Voyager XII.

This spring ( Part No. 11-1102) also fits several other machines (some

will require a spacer to adapt). Following is the machines that also

take this spring:

|

Make

|

Model

|

Years

|

| Kawasaki |

ZG1200

Voyager |

1987-2003

* |

| Kawasaki |

1300

Voyager |

1983-1987 |

| Kawasaki |

ZG1000

Concours |

1986-2002 |

| Kawasaki |

GTR1000 |

1986-1996 |

| Honda |

700

Interceptor |

1984-1985 |

| Honda |

750

Interceptor |

1983 |

| Honda |

CB1000C |

1983 |

| Honda |

CB1100F |

1983 |

| Honda |

CB1100R |

1982-1984 |

| Honda |

CB900F |

1980-1982 |

| Honda |

GL1100

Gold Wing |

1980-1983 |

* Note:

1986 Voyager XII's

use different Progressive Springs since the stanchion tube

diameter was different in the first year of Voyager XII production.

Process of

spring

installation:

-

Remove

front

brake calipers, speedometer cable from front wheel receiver.

-

Release all

air

from front suspension.

-

Remove

front

wheel, fork brace, and front fender.

-

Loosen top

triple

clamp bolt on one of the forks.

-

Completely

remove

the lowest bolt on the bottom triple clamp on the same fork with a

wrench (box or open end).

-

Loosen the

top

bolt of the bottom triple clamp.

-

While

holding the

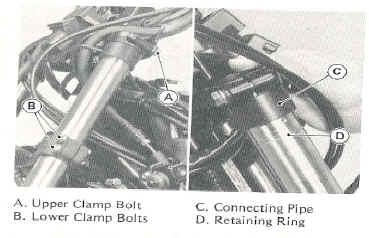

connecting pipe collar up, rotate the fork tube and begin lowering it

in the triple clamps. (See photo 1)

Photo 1

-

Before you

can

remove the fork tube completely from the bottom triple clamp, you must

first remove the retaining ring ( D in the photo), on the fork tube

upper. This retaining ring will become visible after you lower the fork

tube from the top triple clamp. You can remove it by using a slot

screwdriver or other tool to expand the ring and lift it off the top of

the upper fork tube- be careful you do not bend it.

-

After you

remove

this retaining ring, remove the fork tube from the motorcycle.

-

Remove the

top

black plastic fork tube cap.

-

Now the

tricky

part, it's best to have a vise and a friend to help you with this one,

but can be done by yourself with a little patience, muscle, (and maybe

some colorful "french").

-

Wrap a rag

for

good cushioning around the upper fork tube 3 or 4 inches from the top,

or better yet, use about a 3 or 4 inch wide strip from an old rubber

inner tube and long enough to make about 3 wraps around the fork upper

tube, and carefully place it in the vise, only tighten the vise enough

to securely hold the fork tube from slipping down when pressure is

applied to the top plug of the fork tube, not so much as to even begin

to collapse the fork tube ( make sure there enough cushioning to

prevent any marking on the fork tube and do not over tighten the vise).

Test to make sure the fork tube will not slip.

-

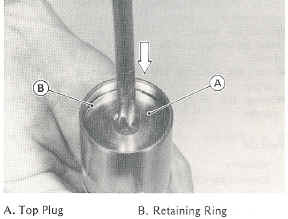

Then by

yourself,

or with a friend's help, press down on the top plug of the fork tube,

and, then remove the retaining ring to allow the top plug to come out

of the fork tube. (See photo below) Be careful to gradually release the

downward pressure as the top plug will have spring pressure on it.

Photo 2

-

Remove top

plug,

oil filter, collar, and fork spring.

-

Remove fork

assy.

from the vise, remove the bottom drain plug on the fork assy. lower,

and drain the fork oil by pumping the fork tube several times until oil

is all out. (Observation: what color is the fork oil? Does it look like

well used (black) engine oil? If so, you waited too long to change the

fork oil!)

-

It is

suggested

that you clean out the fork internals before installing new oil. I did

this by using clean paint thinner and continually flushing it until it

came out clear (put some in, pump the fork several times, drain-

repeat). Do not use gasoline, lacquer thinner, or other strong solvent

(example: auto paint thinners).

-

When you

are

convinced that you have the fork internals clean, then you are ready

for reassembly, make sure you have all of the paint thinner or

equivalent drained from the fork.

-

Fully

compress

the fork and support it so it stands up straight. Before you install

the new fork springs, you must add the required amount of oil. As

mentioned under the tech tip "Front Fork Oil", the best way to bring

the oil up to the required level for the Voyager is to measure from the

top edge of the fork inner tube to the top of the oil level (it should

measure 145mm for Progressive Springs, 140 for stock OEM springs). Use

some kind of measuring tool or improvise to accomplish this, I used a

heavy plastic zip tie, and put a piece of tape 145 mm from the tip of

the tie. I lowered the straight zip tie into the fork inner tube till

the tape lightly touched the fork tube. I then added oil till the fork

oil just showed on the zip tie. Note: Progressive recommends 160mm ± 2mm of oil level. Carl Leo has determined

that 145mm air gap works best for Progressive springs in the Voyager XII

(1200). I had originally used the 160mm air gap level, and found that it

was not enough oil. Use the 145mm air gap measurement .

-

Now,

reinstall

the fork assy. into the vise again like before, install the new

Progressive springs. Now for the difference between the stock fork

springs and the Progressives'. On the Voyager XII's, you DO

NOT reinstall the collar or oil filter like it was when using

the OEM springs. The Progressive springs are longer than OEMs and do

not require these parts. All you'll be installing is the new fork

springs followed by the top plug, then the retaining ring.

-

Now with an

assistant's help (preferred), or if doing by yourself, you need to

reinstall the top plug, hold the top plug down as before and reinstall

the retaining clip.

-

Now

reinstall the

fork assy. back onto the motorcycle. After you get it through the

bottom triple clamp, reinstall the retaining ring back onto the inner

fork tube, See photo 1.

-

Next, by

slightly

rotating the inner fork tube back and forth, guide it back up through

the Connecting pipe (air equalizing collar) and then up into the upper

triple clamp. Tighten all triple clamp bolts. Reinstall black plastic

fork tube caps.

-

Complete

steps 4

thru 22 for the other fork assy.

-

Then

reinstall

the front fender, fork brace, front tire, speedometer cable, and brake

calipers.

-

Your Done

and

ready to ride!!

Water Leak

By

John

Stone MTSV

Problem:

Water leak on the Voyager XII

while

in winter storage. This clears up once the riding season starts. The

leak comes from one side of the horizontal pipe in front of engine

(like a manifold) with two steel lines running into it coupled by a

small length of hose with hose fittings on them. There are two possible

answers:

Solution:

1. Dealer suggests endure the first few

leaky

experiences into spring and ride it the rest of the summer once the

leaks stop. Alternative is to replace seals that dry out in winter,

costs about $100.00.

2. This comes from Alex

Mistal

in Redding CA: Same problem but his leak came from loose hose clamps.

Most of the hose clamps can be tightened without removing any plastic,

but the ones on the top can only be reached if you remove the false

tank, battery, and battery case. Still a job that the average biker

should be able to accomplish without too much difficulty.

Protecting

Fork

Seals

By Chuck

Hoefflin

I

had some difficulty with the fork

seals on

one of my BMW's due to hardened bugs that were stuck on the fork tubes

and damaged the fork seals. I found a Yamaha sport bike that had a

plastic protector that I could adapt. I used that arrangement for the

rest of the time I owned the bike. When I bought my Voyager, the same

problem exists. The fork tube is exposed. So I modified fork protectors

from a Yamaha 4TX-2331G-00 to do the job. For reference, they are 3

5/8" high, plenty to protect the exposed surface of the fork tubes. I

had to modify them for clearance around the stock fork brace- a five

minute job. Cost: less than $5 per side.

|