|

Rear Tire Change

By Mike

Rallis

1. Put bike

on

center stand.

2. Disconnect wiring connectors then remove saddlebags.

3. Remove two bolts for the exhaust for each side. Bolts are under the

rear floorboards and aft.

4. Loosen the bolts to the exhaust just forward of the crossover tube

for the mufflers. One on each side.

5. Remove two bolts from rear crash bars that hold the attachment for

the saddlebag mounts.

6. Remove three bolts on each side of the rear fender flange.

7. Remove the rear fender flange. Disconnect the two wires at the top

under the trunk. This disconnects the license plate light.

8. Lower the exhaust pipes just enough to clear the axle bolt.

9. If you have a Markland trailer hitch, remove it. This will help with

the tire removal.

10. Remove the axle cotter pin and nut.

11. Remove the axle and the brake bolt on the swing arm.

12. Remove the rear brake housing and make sure that the housing isn't

hanging by the brake line.

13. Pull the wheel off the hub towards the right side about two inches.

Be sure that you have a firm grip on the wheel, otherwise something

like hands and/or fingers can get pinched.

14. Pull the wheel out the back end of the bike.

To re-install

the

new tire and wheel:

15. Coat the

shaft

splines with light grease and reattach the wheel back on the hub.

16. Reverse the order above to reinstall.

17. Tighten the rear axle nut to 80 ft/lbs. of torque and the brake

caliper bolt to 72 ft/lbs.

Your ready to

ride!!

Sticking

or Dragging

Brakes

(Will

work for

Front or Rear Brakes)

By Gary Schill

Problem:

You are noticing that your brakes,

either

front or rear, are starting to drag and/or what could be called

moaning. It could also be felt as a minor but noticeable vibration

while the moaning is taking place. It may or may not emit a squeal,

which more likely may be a out-of-service limit brake pad, but if your

brake pads are within service limits and you still hear a squeal or one

of the before mentioned symptoms, or you feel your pads are prematurely

wearing out, then read on.

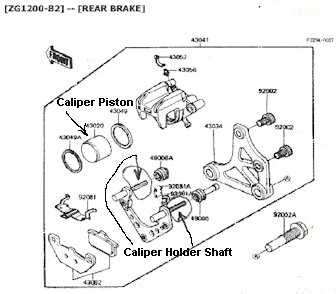

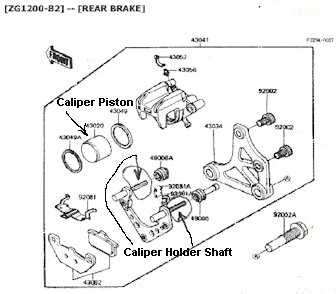

Solution: The problem may be either a

sticking caliper piston, or dry caliper holder shafts and holder holes.

Refer to the diagram below (although it shows the rear brake set-up,

this will work for both front and rear brake).

More than likely, the problem will be dry caliper holder shafts and

holder holes. The caliper holder shafts should slide back and forth

fairly freely in the holder holes, however sometimes these parts which

should be operating in grease, tend to dry out after while and should

be checked at least whenever the brake pads are replaced. First, clean

these shafts and shaft holes using isopropyl alcohol, or ethyl alcohol,

or even disc brake fluid. Do not use gasoline, motor oil, or any other

petroleum distillate, as this will cause deterioration of the rubber

parts. When lubricating these shafts, Kawasaki recommends using a Poly

Butyl Cuprysil grease (PBC is a special high temperature, water

resistant grease). I have used heatproof plumber's grease which is

supposed to be a high temperature silicone base grease, which has

worked well for me so far. After cleaning and greasing the caliper

holder shafts and holder holes, reassemble the brakes and try them

out.

If you notice that your

hydraulic brake fluid is the color of root beer or something similar

(should be mostly clear to very slightly amber) and it has been this

way for some time, your caliper piston MAY be sticking, change and

flush your hydraulic fluids (you should do this at least every two

years, brake and clutch). If you still experience sticking brakes, then

you may need to examine and clean the caliper piston and probably

replace the caliper piston seal and dust cover, also check the master

cylinders as these could also be possibly sticking due to excess

moisture in the brake fluid (that's what turns the fluid the root beer

color.)

Voyager

XII Air

Filter Alternative

By

Bill Bunn

A STP SA3915

replacement

air filter will fit perfectly into the Voyager OEM white plastic basket

by trimming approximately 1/8" off two opposite ends with a razor

cutter. Apply silicon or other sealant in the bottom of the

basket and place the wire side of the new filter down into the

sealant. Don't forget to the reinstall white plastic ladder

looking holders. The cost at our local Advanced Auto Parts

was under $5. A NAPA 6140 or WIX 46140 will also fit with

appropriate trimming.

To get the maximum safe use out of your tires and

maximum touring enjoyment you should:

- Properly maintain all aspects of your

vehicle in accordance with manufacturer's recommendations. Read and

reread your motorcycle owner's manual.

- Never exceed the loading and

accessories

restrictions found in your motorcycle owner's manual, or the maximum

load displayed on the tire sidewalls. Know your loaded vehicle weight!

- Check air pressure at frequent,

regular

intervals, particularly just before and during long trips. Always use

an accurate tire gauge* and check pressures only when the tires are

cold (i.e., wait one hour after running). We have found many cheap

gauges to be off more than 5 psi, so be sure to use a top quality gauge

and preferably one that retains the pressure reading until reset!

- Inspect your tires as often as

possible.

Look for irregular wear, any signs of cracking in the sidewalls and

tread, blisters, knots, cuts or punctures. Immediately remove and

replace damaged tires.

If in doubt, ask your motorcycle tire dealer to

check

your loading, inflation and tires. Remember, your tires stand between

you and a serious accident.

For touring motorcycle loading, follow these general guidelines:

A. Light loads-single rider with some luggage (up to 200 lb.

total)-minimum tire pressure of 32 psi front and 36 psi rear must be

maintained.

B. Heavier loads-dual riding and/or luggage (from

200 lb. total up to maximum motorcycle capacity stated in the owner's

manual)-pressure of 36 psi front and 40 psi rear must be maintained.

Please Note: For any dual riding or fully loaded use, 40 psi must be

maintained in all Dunlop rear tires fitted to touring

motorcycles. In addition to following these recommendations,

notice what your tires are telling you while you're riding. If your

steering response is slow or mushy, or if cornering and braking

response is heavy, there's a good chance your tires are under-inflated.

Vibration or wobble may signal that actual tire damage has occurred and

failure is imminent!

Reprinted

with permission from DunlopTires.com

Installing

Rivco Air Horns

By Rick Jarosch

I

ordered the Rivco Air Horns to "Be Safe and to Be

Heard." The box includes Triple Chrome Plated Air

Horns, mounting hardware, hoses, relay, fuse and very good picture

instructions. It took about one hour to install.

1.

Remove right side lower fairing. Remove 2 bolts holding in stock horn.

2.

Disconnect 2 wires from stock horn and attach them to relay.

The air compressor draws too many amps, and would short out

the horn thumb switch. Run power to relay from

battery with the included wire and fuse, and

attach a ground to other terminal of relay.

3.

Attach mounting bar using 2 old horn bolts.

4.

Use screw clamp, mount air compressor to frame. Keep hoses and wires

away from exhaust.

5.

Put right lower fairing cover back on bike. Use a little water or

saliva, and connect air hoses.

6.

Screw in single mounting bolt. Use thread adhesive to prevent movement.

7.

Attach cover with philip's screw.

Test

horn. At 128-decibels, it is about 4 times louder then the stock horn.

If

the wife complains: Are you spending money on that thing again? You

won't be lying this time when you say "But honey, its for safety"!

Minor

gripe: the installed Air Horn was noticeably pointed to the

right of the bike. I disassembled everything up to step 4 above. I used

2 18" pipe wrenches and moved the mounting bar forward about 1 inch.

After reinstalling everything, the Air Horn now faced straight ahead.

Here

is Rivco's web address:

https://www.rivcoproducts.com/

How

to Use the Voyager

XII

Center Stand

By Gary Schill

Here seems to be a hot topic, especially among Voyager XII owners that

bought their bike used and it came without an owners manual. The

Voyager XII center stand is among the easiest center stands to hoist

the bike up onto- if you know how to do it, and that is not hard. There

are several suggestions that I've seen given on how best to use this

stand, from facing the back of the bike and lifting with the left foot,

to putting a board under the rear tire and then trying, and a few

others. However, most of these appear to be procedures to overcome a

problem that otherwise should not exist. So, before going any further,

I would like to suggest things to do or check that will make using the

center stand easy and effortless.

-

Make sure you

have the

rear suspension air pressure within a reasonable or recommended range,

most times between 35lbs. for solo riders, and about 40 lbs. for two up

using the stock Voyager rear shocks. Your front suspension should also

be within service limits for pressure, about 5-15 for stock (although

at the upper range of this, your front fork springs are more than

likely sacked out and need replaced- use Progressive Springs), if you

have Progressive's, 0 to 10 lbs. should do it. With pressures below

these settings, your bike will set lower and make using the center

stand more difficult than it should be.

-

Tire air pressure

within recommended range. Dunlop recommends 36lbs. front and 40 lbs.

rear for most of their touring tires.

-

Your center stand

is

not missing any parts or broken. This may sound a little odd to

mention, but especially when buying a used Voyager, some of the parts,

especially the 1st stage lever, may be missing because of improper use

of the center stand by someone, which led to 1st stage lever breakage,

and it was never repaired or replaced.

-

Choose a LEVEL or

SLIGHTLY uphill area with a fairly hard surface ( cement, blacktop,

etc.) in which to hoist your Voyager up onto the center stand. Downhill

attempts will be difficult if not almost impossible, you may also put

excessive pressure on the 1st stage lever, possibly breaking it (that's

why some used Voyagers are missing this lever), and your bike will have

a tendency to fall forward off the center stand. If the bike sits on

too much of an uphill grade, you'll have a very difficult time getting

it off.

-

Make sure your

transmission is in neutral.

Here we go:

|

|

1. This is what your center stand

should look like peeking out from under your stock mufflers on the left

hand (as sitting on the bike) side of your Voyager. The tubular "pipe"

is the 1st stage part of the center stand (red arrow pointing to it),

if this part is missing, you should make arrangements to get the broken

part re-welded on if you have it, or fabricate one to take it's place.

The larger part with the foot pad on it, is the 2nd and main stage of

the center stand. |

|

|

2. With the machine on level or very

slightly uphill surface, hold the bike upright while standing on the

left side, front wheel pointed straight ahead. Have your left hand on

the left handlebar grip and your right hand on the rear passenger

chromed grab handle. Put your right foot on the 1st stage lever and

gently lower into position until the center stand "feet" are resting on

the surface and the bike feels "centered" on them. You may have to pull

the bike slightly rearward while doing this, and you want both center

stand feet on the surface and fully forward. |

|

|

3. Now place your right foot on the 2nd

and main stage of the center stand (the one with the larger foot pad on

it), and just use a moderate down pressure on it. If you are doing this

on level or slight uphill surface- hard surface, (it can be done in

gravel, but will need to be more delicately done), the bike should

fairly easily pop right up on the center stand. If not, review the

steps here and make sure your stand is mechanically and physically

sound. With very little practice, you should be a pro in no time!

|

Voyager

XII Oil

Drain Plugs

Locations

By Gary Schill

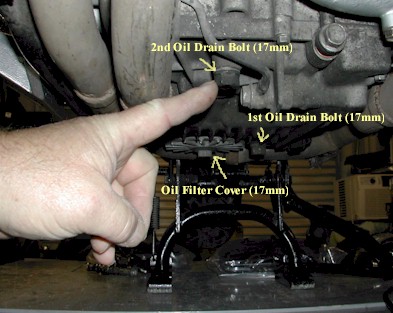

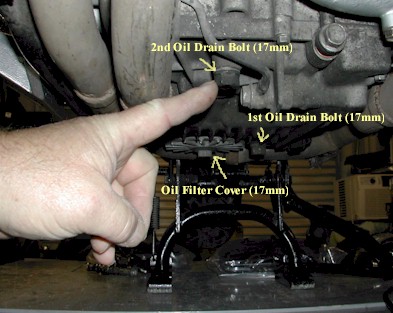

Most motorcycles when draining the oil, you remove one drain plug and

possibly remove the oil filter to remove most of the oil from the

engine and transmission. However, with the Voyager XII, things are just

a little more complicated. With the Voyager XII, you need to remove TWO

drain plugs (17mm bolts) and the oil filter (which also has a 17mm bolt

in the middle of it to remove) to completely drain the oil. As usual

with any engine, it is best to warm the engine first to facilitate

easier and more complete draining. Have the engine warm, not hot, and

make sure the exhaust pipes are not hot when draining the oil so to

lessen the chance of burning yourself in case you come in contact with

the exhaust pipes or spill some oil on you when you first remove the

drain plugs. If you do not remove both drain plugs and the oil filter,

you will not have all the old oil out. See picture below that was

submitted by Fritz previously on the AVA message forum for location of

both drain plugs and the oil filter cover. Fritz is pointing to the

second drain plug that is missed by many unfamiliar with this Voyager

peculiarity. Do not remove any non-17mm bolts as they are for other

things, the bolt next to the 2nd oil drain bolt for example is for

engine oil to pass through. The bolt barely visible in the upper right

hand corner is one of the engine coolant drain bolts.

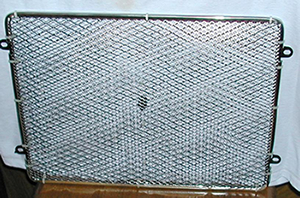

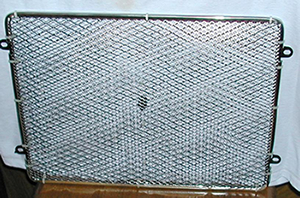

Radiator Grille Dress-Up

By "Wild Bill" Chandley

I discovered some anodized

aluminum mesh

grille material in the J.C. Whitney catalog for $19.99. It's

available in Red, Blue, Black, and Silver... and comes in either a

Small or Large diamond pattern. It's intended for automotive

use, like a decorative insert behind the grille opening of a car or

truck... but I noticed the size was large enough to fit the radiator

grille of my Voyager XII (with substantial material left

over) and figured it might be suitable for use as a decorative

covering.

So I ordered some

in Silver, and it

arrived yesterday. I wasted no time in fabricating my new

radiator mesh grille as follows:

(1) I began by installing some plastic chrome edging around

the black-painted perimeter of the OEM grille. After

cutting a piece of the new mesh to the size of the OEM grille, I

realized I'd have to take off the edging

again (in order to fit the outer lip of the new mesh

under it) and reinstall it. That's what prompted me to use

the wire ties --- because the adhesive inside the chrome edging is only

intended for a single use, and I was afraid it wouldn't stay

put. I gave some thought to putting more (new) chrome edging

on, but since the wire ties are hidden by the outer radiator

cowling anyway, I'll probably just leave them as is.

|

|

|

(2) I'd previously

installed the same plastic chrome edging on the inner lip of my

radiator cowling (rear view).

|

(4) Here's the

radiator grille (with new mesh installed) just sitting in the opening

of the cowling (not centered vertically). |

Anyway... I think it turned

out pretty well as a $20 alternative to having the

OEM grille chrome-plated. (Now I'm gonna see what I can do

with fabricating some mesh inserts for my side cowlings out of

the same material).

P.S. - If I do any more of

these, I'll

definitely cut out the mesh grille BEFORE putting on the plastic chrome

edging. Also, the diamond openings in the new mesh are

smaller than the OEM openings... there was a Large Diamond mesh listed

by J.C. Whitney, but since no measurements were given, I was afraid the

openings might be too

big. (Actually, the small openings may work out

better, as far as keeping bugs and debris out of the radiator...).

|

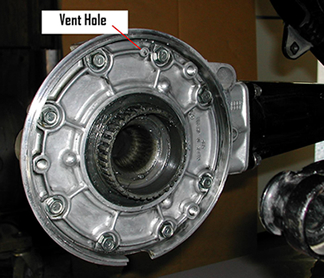

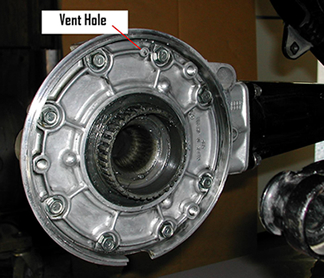

Voyager XII's mostly came

stock

with a vent hole in the final drive, later, some thought it was better

to plug this hole to curb oil leakage from this area. However, it was

later found that higher than normal (anything above ¼" below final drive fill hole)

contributed to most if not all the oil leakage, and plugging the final

drive vent hole actually could increase oil leakage because of pressure

build up as final drive oil heated up and forcing oil past the seals,

therefore, it was recommended to re-open the hole if previously plugged.

Here is a picture of final drive vent location. 1/16th

inch hole is good. Just enough to vent the drive. Make sure you cover

up the gear to keep metal chips out. I used a shop vac and hold it next

to the drill bit while drilling. Sucks up all the metal bits. |

For

instructions to

re-open this final drive vent hole, see below:

Drilling

a final drive

After you

remove the

rear wheel, cover the final drive gear with a rag so you don't

get chips of metal

on it. Myself, I use masking tape to tape a rage to

the final drive face to make SURE no chip get on the gear. A

little note... look at the amount of grease on the gear. Don't

use anymore than that amount. I've seen too many mechanics

putting WAY TOO much grease on that gear. It doesn't take much

grease to work. If you use too much grease, when the final drive builds

up heat, this grease will turn to an oil and

will be thrown outward against the inside of the hub and leak

out onto the wheel and tire. Oil on tires are not a lot of

fun. :O)

Use a 1/16th

drill

bit. measure back from the tip of the drill bit about 3/16th

to 1/4 inch and wrap a piece of electrical tape around that

point. This is to give you a guide as to how far to drill into

the final drive case. Its just so you don't drill through

the

outside of the case. The bit will go in more than that but

its a good reminder to not drill too far. NOTE: I use a

shop

vac and hold the hose up to the drill bit while I'm drilling.

Most of the time it will suck up all the chips and none will

even fall on the rag. No matal chips should go into

the final drive case

because it the nature of the drill bit to pull metal out away from

the hole. You can use a small piece of wire to poke in the

hole to make sure it was drilled all the way through. Even in

the worst case scenario that a small chip would get into

the final drive,

it would only get eaten up in the gears. You should have

no problems as long as you pay attention.

Alternator

Rubber

Dampener Location and Inspection

By Fritz Wells (The Masked

Rider)

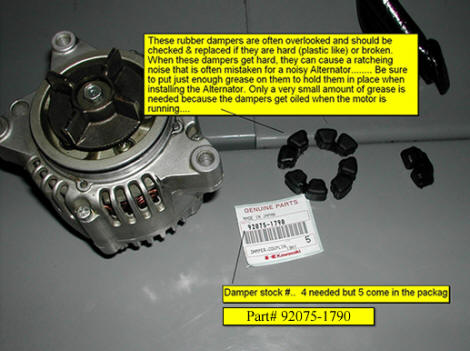

|

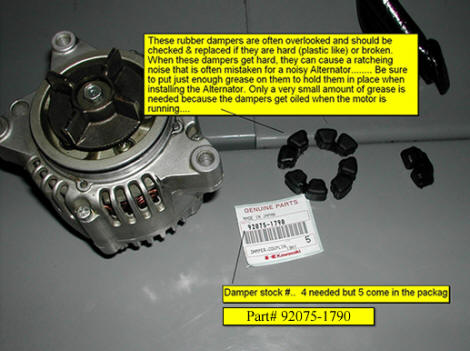

Here

are some pictures

showing the rubber dampeners that help keep the Alt noise down. These

rubber dampeners should be med soft rubber. If they are hard like

plastic, they should be replaced. Noise coming from the Alt. area does

not always mean the Alt is the problem. Hard dampeners can make a lot

of noise.

|

|

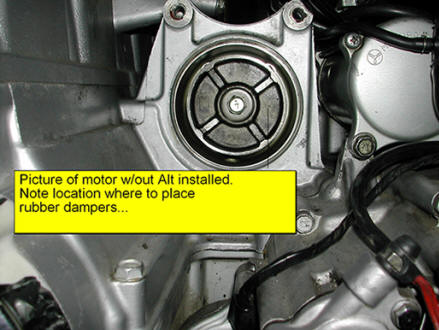

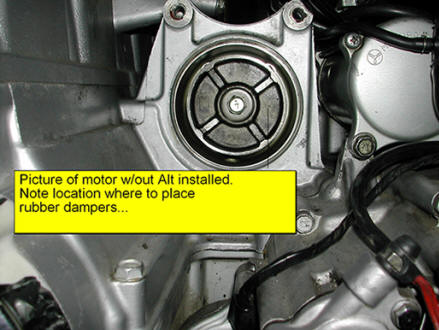

View

of

where the alternator is mounted on a Voyager XII. Removing or

installing a rebuilt alternator is not a hard job, they are fairly easy

to get at and are straight forward in removal and installation. Note

that the stock alternators are 35 amp output and the only parts

available from a dealer is the alternator brushes. If your alternator

is unable to be rebuilt for some reason, check out the alternatives on

the AVA's Dollar4Dollar page. |

|

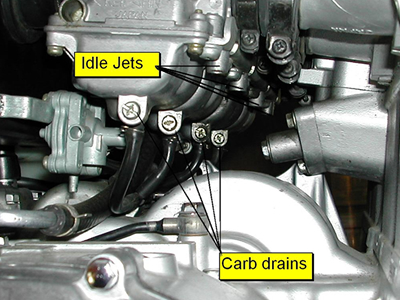

Carburetor Drain

Screw and Idle Jet Adjustment Locations

By Fritz Wells (The Masked Rider)

|

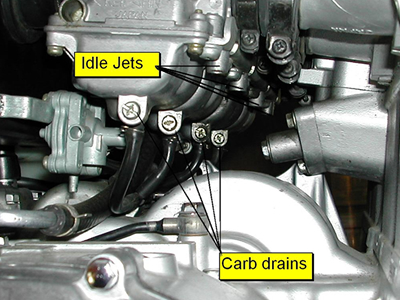

Here

is

another excellent picture from Fritz. It shows the locations for the

carb drain screws (to drain carburetor float bowls- Voyager XII), and

where the idle jet adjustment screws are. It must be noted that the

idle jet adjustment screws are hidden by soft plugs to prevent

unauthorized adjustments from factory settings to satisfy pollution

requirements.

|

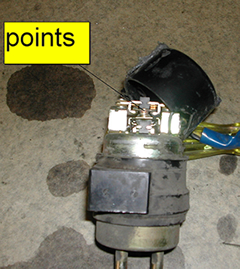

Fuel

Pump Point Access

Pics By Fritz Wells (The Masked Rider)

Text by Gary Schill

When you might think that your fuel pump has bought the farm, it is

probably a 90% chance that the only problem is just dirty or pitted

fuel pump points. When the points don't make good contact, the pump

doesn't work, and your bike will not start or may not run properly if

it does. The Voyager fuel pumps (Voyager XII's), use a point system

which may become corroded, much the same way distributor points used to

do on cars. If the points become corroded, or do not make good contact,

they will need cleaned. Kawasaki has tried to solve the problem of

corroded points by sealing the points on 1990 and later model bikes. If

your bike is pre-1990, it will be easier to service the pump, as they

are not sealed. This article will show you how to get to the points if

it is 1990 or later, but the location and construction of the pumps are

the same. Although some have adapted other type fuel pumps to the

Voyager, it must be noted that the Voyager pumps are a four wire pump

and not the two wire pump as some are. The OEM Voyager pump has some

safety features on it that will only work when all four wires are used.

Two wire pumps can be used for emergency or even more long term use,

but they will not have some of the safety features that the OEM will.

So, you feel your pump isn't

working. Look at the following

pictures to see how to disassemble the pump and general features and

locations of the pump and connections.

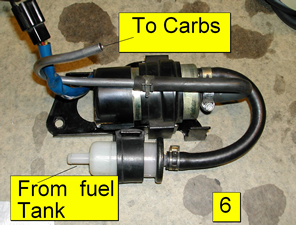

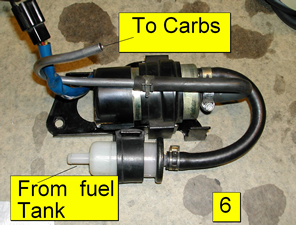

Although

Fritz had intended this to be one of the final steps to pump point

cleaning, to show the routing, I used it here to show what the pump

actually looks like along with the fuel filter which is mounted below

it. To find the pump, one must look on the right side of the bike, just

above and behind the rear wheel brake fluid reservoir. After you

complete the point cleaning or reconditioning, refer back to this

picture for routing of the hoses from the fuel tank and to the

carburetors.

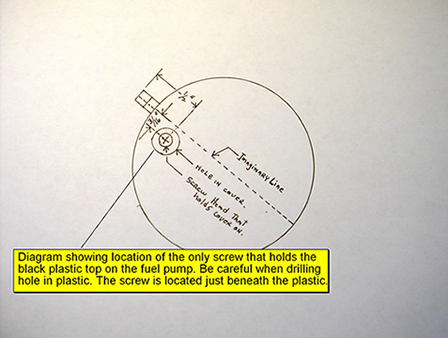

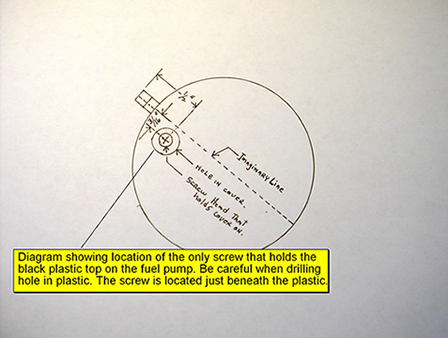

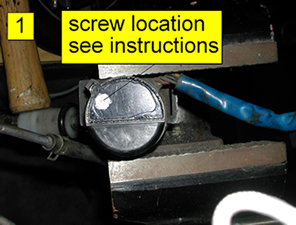

As

noted in the yellow

box on the diagram to the right, this shows where the screw is located

that holds the pump cover onto the pump. This screw may be more easily

seen in pumps that came as original equipment on Voyager XII's from

1986 to 1989, but after that were sealed. Use this diagram to plot

where to drill a very shallow hole to access this screw (the only one

holding the pump cover on). Only drill just through the plastic cover

as the screw is directly below it.

With

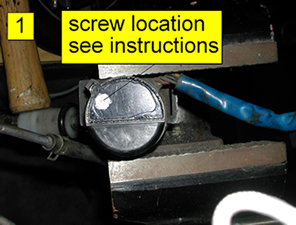

the fuel pump removed from

the motorcycle and placed in a vise, use the diagram above to mark

where to drill a shallow hole to access the fuel pump cover mounting

screw. That location is shown in white here. This is where you will

drill a shallow hole or otherwise remove a little plastic from the fuel

pump cover to access the pump cover mounting screw.

|

|

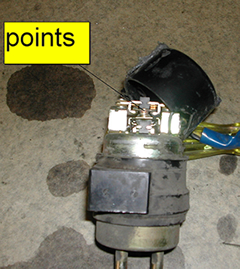

| Here is shown the hole that was

drilled or otherwise plastic was removed to expose the pump cover

mounting screw. |

And here are those little bugger

of a points that cause most of the problems (when and if a problem

occurs) with the XII fuel pump. Inspect the points, clean and dress as

required. If the points are pitted,

file them smooth. A good electrical cleaner such as found

at Radio Shack® or other electronics

stores is best to use. After cleaning, you may want to give the points

a light coating of WD40, LPS1 or similar waterproofer. |

After

you have the cover reinstalled and the cover mounting screw tightened

up, cover the hole you made to expose the cover mounting screw with

metal tape to reseal it. Remount the fuel pump and filter assembly back

on the bike being careful to properly hook up the hoses as shown in the

first picture of this article (noted as #6). If it has been some time

since you replaced your fuel filter, now would be a good time to do

that since your right there. There are a few alternative fuel filters

for the Voyager XII's listed on the

Dollar4Dollar

(new window) page if you don't want to use or cannot get an OEM fuel

filter. After all is back together, enjoy the ride!

Brake Sponginess

As

related to Mike McGee from

Kawasaki

Technical Rep. Brian Fugate

Before I left on a trip from Florida, I topped off the rear brake

master cylinder. Then I forgot to put the cap back on for a

whole day (South

Florida

humidity). Knowing it was contaminated by moisture, I pumped

out the whole system, and refilled with DOT 4. When I pumped

and bled the brake system to get out the air, I could not get any pedal

pressure. I bled the brakes 20 times. No

pedal. I rode to Americade with no usable rear brake and

didn't have time to go to a dealer to have it checked. When I

stopped second night in Pennsylvania,

I bled it 30 more times. No help. When I got up to

Americade, I spoke to

Kawasaki's

Technical Representative, Brian Fugate. He took the time to

listen to the problem and the story. We opened the rear

master cylinder reservoir cap and tried it a few times. No

luck. Finally, after much thought, he told me to hold the

pedal down, left the nipple open and did this: He grabbed

both sides of the rear brake caliper and squeezed them

together. Out popped a large bubble of air that was trapped

in the caliper. He closed it and on the next pump and bleed,

the rear pedal was hard as a rock. I had read the owner's and

service manual. No mention was made of this. I

never heard anyone ever talk of this before. It was a

revelation. If you have the same problem, try this technique.

CB/Radio Display

Not

Working Correctly

The channel display on the CB controller no

longer

works

correctly, and the unit may quit transmitting. There is a

click when the push-to-talk button is depressed but the TX does not

light up. It does receive however and change channels but with no

display, it is not possible to know what channel the unit is on. The

back lighting on the unit also works.

This problem

is more

common than you might think. One method of correction that works for

many, is to disconnect the hot lead on the battery for about a minute,

then reconnect it. This will reset the controllers and most likely will

fix your problem. If that doesn't work, you may then want to check the

connections on the back of the CB display for any loose, disconnected,

or corroded connections.

|

Although

Fritz had intended this to be one of the final steps to pump point

cleaning, to show the routing, I used it here to show what the pump

actually looks like along with the fuel filter which is mounted below

it. To find the pump, one must look on the right side of the bike, just

above and behind the rear wheel brake fluid reservoir. After you

complete the point cleaning or reconditioning, refer back to this

picture for routing of the hoses from the fuel tank and to the

carburetors.

Although

Fritz had intended this to be one of the final steps to pump point

cleaning, to show the routing, I used it here to show what the pump

actually looks like along with the fuel filter which is mounted below

it. To find the pump, one must look on the right side of the bike, just

above and behind the rear wheel brake fluid reservoir. After you

complete the point cleaning or reconditioning, refer back to this

picture for routing of the hoses from the fuel tank and to the

carburetors.

As

noted in the yellow

box on the diagram to the right, this shows where the screw is located

that holds the pump cover onto the pump. This screw may be more easily

seen in pumps that came as original equipment on Voyager XII's from

1986 to 1989, but after that were sealed. Use this diagram to plot

where to drill a very shallow hole to access this screw (the only one

holding the pump cover on). Only drill just through the plastic cover

as the screw is directly below it.

As

noted in the yellow

box on the diagram to the right, this shows where the screw is located

that holds the pump cover onto the pump. This screw may be more easily

seen in pumps that came as original equipment on Voyager XII's from

1986 to 1989, but after that were sealed. Use this diagram to plot

where to drill a very shallow hole to access this screw (the only one

holding the pump cover on). Only drill just through the plastic cover

as the screw is directly below it.

With

the fuel pump removed from

the motorcycle and placed in a vise, use the diagram above to mark

where to drill a shallow hole to access the fuel pump cover mounting

screw. That location is shown in white here. This is where you will

drill a shallow hole or otherwise remove a little plastic from the fuel

pump cover to access the pump cover mounting screw.

With

the fuel pump removed from

the motorcycle and placed in a vise, use the diagram above to mark

where to drill a shallow hole to access the fuel pump cover mounting

screw. That location is shown in white here. This is where you will

drill a shallow hole or otherwise remove a little plastic from the fuel

pump cover to access the pump cover mounting screw.